FOOD PROCESSING INDUSTRIES

|

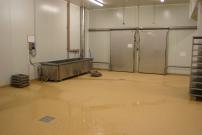

These industries include dairy, beverages (brewery, soft drinks, juices, etc.), bakeries, fish, meat and vegetables. They must meet very high hygienic standards, such as HACCP and at the same time be resistant to aggressive media like chemical and acid exposure, not to mention heavy traffic. For decades, clinker tiles and their technical properties have been widely used in these environments, unfortunately due to their limited range of colors and sizes have been slowly phased out by newer products. Fully vitrified tiles become more and more prominent in this segment due to their improved resistance to damage, shape, sizes availability in colour and their improved Technical properties. |

One shape ideal for these environments is a hexagonal shape. It has all the characteristics required to withstand heavy traffic, point and dynamic loading and is ideal for environments where floors must be designed to slope towards a drainage system, since using this shape, the floor may be molded to match the slope. As these floors are subjected to lactic acids, fat, blood, hot water, nitric, citric or caustic acid in various concentrations, not to mention thermal exposure, the floor systems must be able to withstand all of these factors and meet these criteria, notwithstanding the responsibility end users face for properly maintaining the floors. |

It should be noted that the solvent resins which used to be employed to join individual ceramic tiles are no longer permitted in a food processing environment because of their fumes which occur during their use. These had greater chemical resistance than the joining resins used or permitted today, the end user must assume the responsibility for proper maintenance to ensure the longevity and performance of these floors, especially joints. Expansion joints or profiles used within these environments should be made from stainless steel and have a chemical and acid resistant filling compound, such as Ployurea, Polyurethane or Flexible resin. |

APPLICATION SYSTEM

VIBROCHEM 40®

A BONDED SYSTEM flooring system is placed directly upon an existing supporting concrete structure. These systems have chemical resistant bond slurries and stainless steel expansion joints

VIBROCHEM 60®- NON-BONDED SYSTEM ( Floating system)

These systems are placed upon a separation layer and have added reinforcement. For their supporting substructure, chemical resistant bond slurries and stainless steel expansion joints are introduced. Separation layers are of various types, depending upon the application and the environment where they are to be used. These may be: PE-foil, bitumen type, epoxy type or rubber type.

For further information contact us!